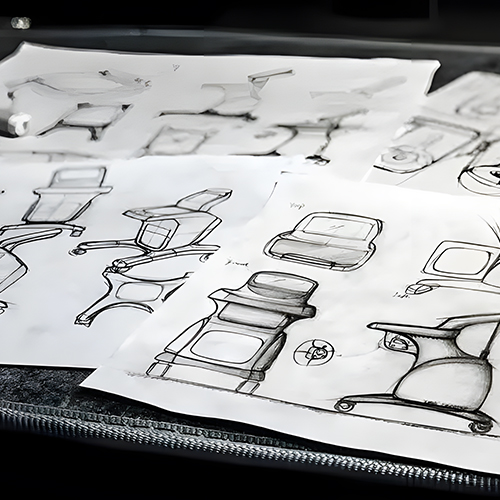

The costs of using standard production methods can skyrocket if you need unusual dimensions, materials, or other specifications for your manufactured product. Machining a block with bearing or component-holding openings and chamfers requires intricate fresagem, viragem, and drilling. What if you create one or two parts for your prototype while still in the planning and design stages? Services like electrical discharge machining, i.e., EDM machining, might be a more time and resource-efficient alternative to traditional machining techniques like milling and turning. A succession of current discharges between two electrodes separated by a dielectric bath liquid removes excess material from a workpiece in this manufacturing process.

In this comprehensive guide, we will discuss everything you need to know about operating an EDM machine and the functions of its different components.

Basic Operation:

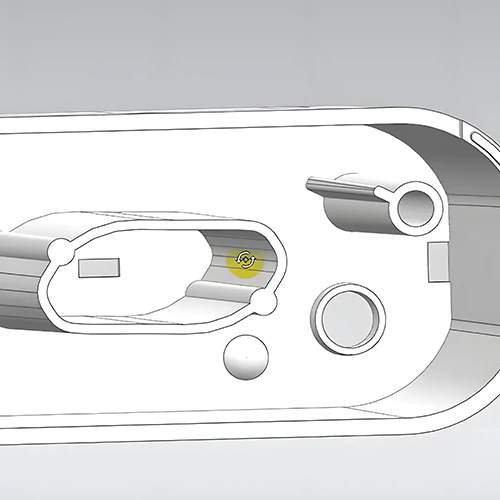

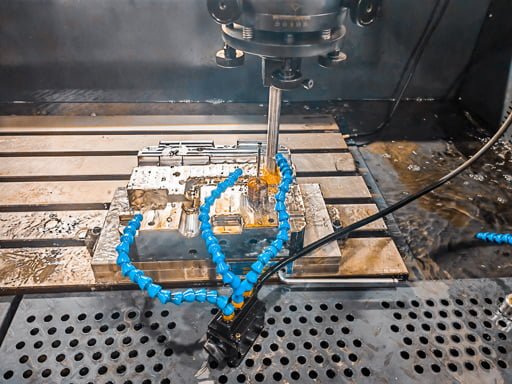

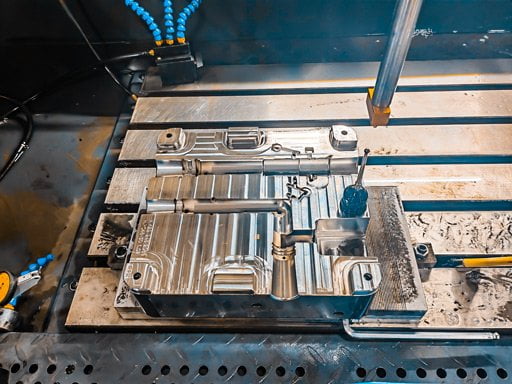

EDM stands for Electrical Discharge. EDM Machining is a metal-cutting procedure that uses electricity, similar to a plasma cutter but done underwater. The method is widely used in the production of moldes de injeção. The method can range from using a tiny diameter metal tube to create a precise hole in a metal block to machining a toy shape in a metal block for injection molding. I’ll teach you how to build your EDM machine using simple hand tools and components from your local hardware shop.

Electrical discharge machining removes metal comparable to plasma cutting but on a much smaller scale and underwater. As seen in the preceding stages, the tool is generally above the workpiece and wired to the positive voltage. In contrast, the workpiece is immersed in distilled water (a dielectric fluid that does not conduct electricity) and wired to the negative voltage.

Before they touch, the tool will emit a spark as it approaches the workpiece. The spark now warms the tool and the workpiece, melting a small portion of both. The molten metal quickly cools in the water, and the water flow drives the metal particles out of the space between the two pieces. This operation is done several times until the workpiece is etched away as the negative of the tool shape.

The tool is often placed on a vertical linear slide, allowing precise positioning. If the tool is too far from the workpiece, no spark will appear; if the tool is too close to the workpiece, the two components will fuse or weld together. The tool is frequently pulled closer to generate a spark, then moved away to allow flushing and reduce the risk of fusing with the workpiece.

EDM Machining Types

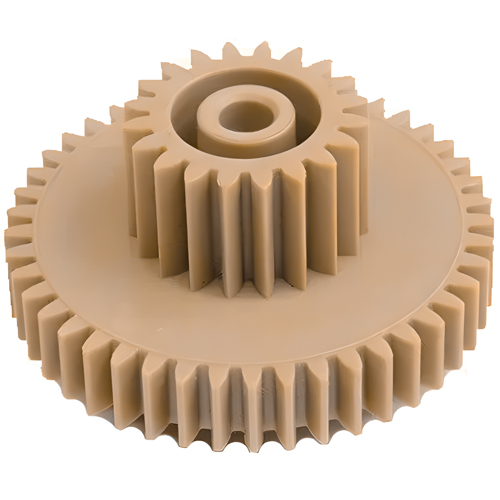

Machining with a sinker discharge is called die EDM, classical EDM, or the Ram EDM technique. It can make intricate geometries that are impossible to achieve using wire EDM. Graphite or copper is often used as the electrode material. It is typically machined into a precise form that is the inverse of the intended final geometry of the item.

After the electrode has been sculpted, a process known as “electrode wear” causes the workpiece to be damaged by sparks to form the appropriate geometry. Sinker EDM, in contrast to Wire EDM machining, is capable of performing both partial cuts and cuts that go all the way through the workpiece.

Wire Cutting Electrical Discharge Machining

In this form of EDM, a wire is utilized as an electrode. The wire is continually and automatically fed during the operation using a spool. Ionized water is typically used as the fluid, and brass or copper is typically used for the wire.

To assure compatibility and prevent corrosion, it is highly advised that the workpiece material and wire electrode materials be inspected to identify the appropriate process parameters for the electrical discharge machining technique. Since wire electrodes are used to cut the workpiece, it is only possible to make cuts that go through the entire thickness of the workpiece.

Hole Drilling

Drilling is performed with the third type of EDM, which is known as electric discharge machining. Compared to more traditional drilling technologies, hole drilling EDM can create tiny and deep holes, which are notoriously tricky. In addition, hole drilling using EDM is exceptionally clean and does not call for any deburring to be done.

The electrodes used in this technique take the form of tubular structures, and the dielectric fluid is circulated through them. The electrode erodes or slices the workpiece in a way analogous to the other EDM machining forms. Still, the electrode never makes contact with the workpiece because of the discharged gap. Compared to the deflection the drill bit experienced during conventional drilling techniques, this results in significantly less bending of the tube electrode.

Machine Components:

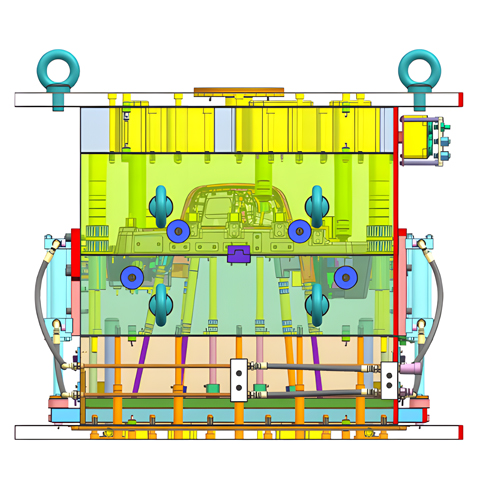

While the three varieties of EDM are used differently, the structure of each system is the same. It includes the following:

Computer Numerical Control (CNC) is the unit that processes the tool’s route. Several software packages can simulate and design these CNC codes for your geometry.

Voltmeters and ammeters are electrical potentials and current measuring instruments.

Alimentação eléctrica: the source of energy for the spark.

Material to be cut: workpiece

Cutter: a tool for cutting the workpiece.

The dielectric fluid acts as a barrier between the cutter and the workpiece. It also regulates the electrical discharge and absorbs heat during the operation, allowing the workpiece to cool. Another function of the dielectric fluid is debris removal.

The filter maintains the dielectric fluid’s state (resistivity/conductivity), water temperature, and other parameters. Debris that could alter such conditions is filtered away, keeping the system clean.

Pump: regulates the dielectric fluid flow, allowing the Maquinação por EDM equipment to function constantly.

Fixtures are boards, jig tools, and other work-holding systems that keep the workpiece and cutter steady and in place.

EDM Machining Characteristics:

Dielectric fluid is used in EDM to submerge the electrode and the workpiece. It removes material from the workpiece by eroding or slicing it with an electric spark to achieve the appropriate shape. CNC programs control the electrode’s motion, and it’s essential to grasp a few fundamentals to ensure a smooth procedure.

Discharge Gap:

To generate sparks between the electrode and the workpiece, there must be a space, sometimes called a “discharge gap,” which is usually in the 0.005 – 1 mm range. Sparks are not produced if the electrode and the workpiece are in touch. A servo mechanism in the EDM system regulates this gap and the movement of the electrode.

Electrode Wear Ratio:

This ratio is calculated by dividing the volume of material lost from the tool electrode by the amount of metal retrieved from the workpiece. It is sometimes represented as a percentage of the overall mass loss of the instrument divided by the total amount of work done.

Polarity

In this approach, one must be positive and the other negative to apply a voltage between the workpiece and the electrode. So when the electrode is negative and the workpiece is positive, it is usual practice to refer to the situation using the term “positive polarity” or simply “polarity.” Likewise, when the electrode is positive and the workpiece is negative, this configuration is referred to as having “reverse polarity.”

We suggest you become familiar with the mix of the electrode and workpiece materials you will use to identify which settings and process parameters will work best for your application. Polarity can affect the rate of material removal, often known as the “electrode wear ratio,” as well as the surface roughness, which in turn can affect wear, speed, and stability.

Removal Rate

The pace at which the spark eliminates material from the workpiece. Common mass or volume units, such as [g/min] or [mm3/min], are used in quantification.

Conclusão:

In conclusion, this article has covered the fundamentals of electrical discharge machining. With the knowledge gained from this article, we hope that you can confidently incorporate EDM into your production toolkit, knowing its advantages and limitations and how it compares to other techniques.